|

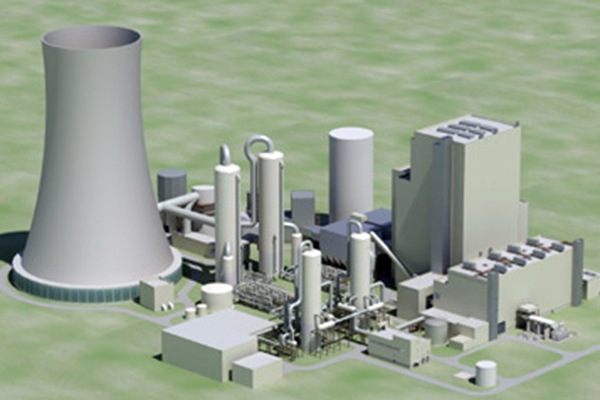

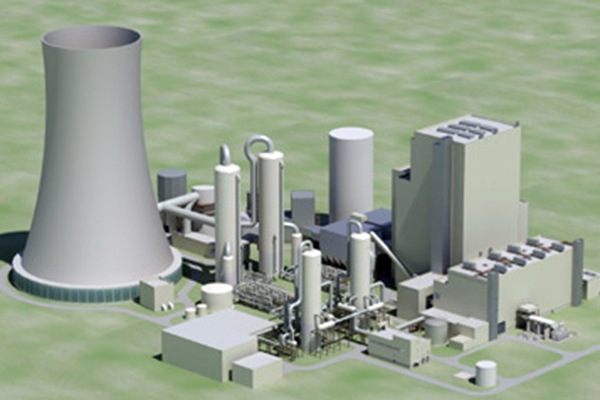

The Project refers to a new Lignite-Fired Steam Electric Unit (Ptolemais, UNIT V), to be erected in the area of the exhausted lignite minefields of Komanos, at a distance of approximately 4km from the existing Ptolemais SES.

The Unit shall be of maximum gross power output (Maximum Continuous Rate (MCR)) operating at pure condensing mode 660MWe capable to provide in the future, thermal load up to 140MWth for the district heating system of the Municipality of the city of Ptolemais.

The UNIT shall be of pulverized fuel firing with supercritical steam conditions and reheat, cooled by cooling water circulating in a wet type natural draft cooling tower.

The UNIT shall be complete with all necessary systems, such as:

- Fuel handling, feeding and preparation system (pre-crushing, drying and pulverizing),

- Steam generator with auxiliary systems,

- Flue gas heat recovery systems (for maximizing Unit’s efficiency),

- Steam turbine-generator set with auxiliary systems,

- Condensing system and condensate/feedwater treatment (preheating and conditioning) systems,

- Cooling tower and cooling water systems (open and closed cooling water systems),

- Flue gas cleaning systems as mentioned in previous paragraph,

- Clean gas system for the discharge to the atmosphere of the flue gases, via the cooling tower, without by-pass stack,

- By-products handling and transportation systems (wet and fly ash, gypsum and sludge).

The unit shall consist of the following buildings, structures, facilities, site improvements and area works to be designed and constructed.

1. Crusher House

2. Transformers Yard

3. Turbine House

4. Electrical Building

5. Boiler House

6. Electrostatic Precipitators

7. Fans

8. Flue Gas Heat Recovery System

9. Absorber and Absorber Building

10. Recirculation Pumps Building

11. FGD Dewatering and Limestone Preparation Building

12. FGD Electrical Building

13. Limestone Unloading Building

14. Limestone Storage Silo

15. Void

16 Process Water Tank

17. Limestone Slurry Tank

18 Slurry Emergency Storage Tank

19. Gypsum Storage Silo

20. Fly Ash and Wet Ash Silos

21. Electrical Building for Ash Handling

22. Waste Water Treatment Plant (S1)

23A. Diesel Oil Unloading and Pumping Station

23B. Diesel Oil Storage Tank

24. Auxiliary Steam Generating Plant and Diesel Oil Tank

25. Daily Diesel Oil Tank

26. Cooling Tower

27 Cooling Water Pipes

28. Raw Water Storage Tank and Pumping Station

29. Reverse Osmosis Building

30. Desalinated Water Storage Tanks

31. Demi Water Plant and Chemical Laboratories

32. Demi Water Storage Tanks

33. Waste Water Treatment Plant (S2)

34. Sanitary Waste Water Treatment Plant

35. Lignite Conveyors

36. By-Products Conveyors

37. By-Products Transfer Station

38. Workshops Complex (Mechanical – Electrical)

39. Stores for Heavy and Light Spare Parts

40. Stores for Lubricants, Chemical, Inflammable materials

41. Outdoor Storage Area

42 Weighing Station

43. Administration Building

44. Parking for Administration

45. Canteen

46. Vehicles Workshop – Refuelling Station – Garage

47. Main Gate House – First aid Station – Entrance Shed

48. PPC site offices

49. Parking

50. Bus stop Shed

51. Roads and Pavements

52. Channels and Galleries for pipes and cables

53. Rainwater Drainage System

54. Industrial Waste Water Drainage System

55. Sanitary Sewage System

56. Access road

57. Anti Flood Protection

58. Fence

59. Landscaping

|